Reliable, Proven DesignPAYBACK drives mount directly on the shaft of any a.c. motor, which makes the drive ideal for retrofit applications as well as new installations. Each drive has a simple shaft-locking device that makes it easy to attach or remove the drive from the motor, without the need for shaft keys. Output sheaves and drive bearings are mounted close to the motor's face, directly over the motor shaft. This allows for maximum belt tensioning without causing stress to the motor's shaft and bearings.

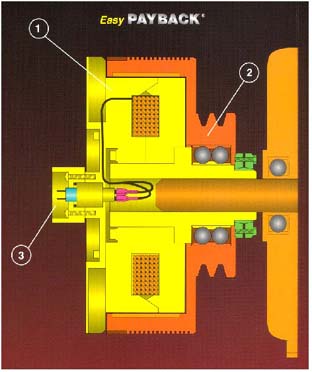

The electromagnet (1) is affixed to the motors shaft with a shaft locking device so as to run continuously at motor speed. The armature / pulley portion (2) connects to the load. These two elements are separated by ball bearings which maintain a constant air gap between the two portions. When current is applied to the coil of the electromagnet via the brush-less rotary coupling (3), a polarized field is produced, magnetically coupling both components and causing the output portion to turn in the same direction as the motor. Output speed is dependent on the strength of the magnetic field which is proportionately controlled by the amount of current applied to the electromagnet. All of Coyote's

patented drives are designed with a single air gap to minimize losses

and maximize performance. The inner drum surface on every PAYBACK

drive is copper lined which improves the overall efficiency of the

drive. This is an important energy saving advantage over any drives

that do not incorporate this copper technology. |

Basic

Principle of Operation:

Basic

Principle of Operation: